How are Low Lint Wipes made?

The process

![]() Censol Non Woven wipes are made by a process called hydroentangling. This is basically shooting thousands of high-pressure (up to 2000psi), needle-like jets of water at a random group of blended fibers.

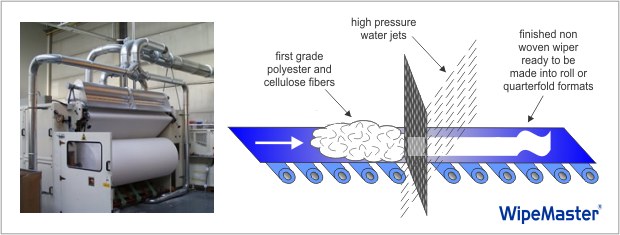

Censol Non Woven wipes are made by a process called hydroentangling. This is basically shooting thousands of high-pressure (up to 2000psi), needle-like jets of water at a random group of blended fibers.

![]() The jets entangle the fibers into a fabric, which is then dried and wound into a fabric roll. Fibers may be entangled to form a strong yet soft sheet structure with either a repeating pattern (called apertured or creped) or no pattern.

The jets entangle the fibers into a fabric, which is then dried and wound into a fabric roll. Fibers may be entangled to form a strong yet soft sheet structure with either a repeating pattern (called apertured or creped) or no pattern.

This is good because...

![]() The hydroentanglement process produces a single sheet of material from a mass of fibers resulting in good wet and dry strength, excellent absorbency and low lint characteristics.

The hydroentanglement process produces a single sheet of material from a mass of fibers resulting in good wet and dry strength, excellent absorbency and low lint characteristics.

![]() All this coupled with excellent chemical compatibility, make the wipes ideal for use with oils, solvents, alcohols and practically any other fluid.

All this coupled with excellent chemical compatibility, make the wipes ideal for use with oils, solvents, alcohols and practically any other fluid.

![]() The brands below are just a small sample of wipers that we can provide. To see the entire range of wipes please click on the brand of your choice:

Wipemaster®,

Dupont™ Sontara®,

Tork®,

Chicopee® and

Kimberly Clark®

The brands below are just a small sample of wipers that we can provide. To see the entire range of wipes please click on the brand of your choice:

Wipemaster®,

Dupont™ Sontara®,

Tork®,

Chicopee® and

Kimberly Clark®

5818

5818